Built an AI Agent That Predicts Inventory Needs—Here’s How It Works

Managing inventory is a delicate dance.

If you stock too little, you get the dreaded “out of stock” notice, leading to lost sales and unhappy customers. If you stock too much, you’re tying up cash in warehouse shelves and risking getting stuck with products nobody wants.

For decades, the solution has been simple, static rules: “When Item A’s stock level hits 50 units, reorder 200.”

This model is purely reactive. It works perfectly, right up until the moment it doesn’t. What happens when a marketing campaign goes viral and demand doubles overnight? Or a shipping delay pushes your lead time out by an extra week? Suddenly, your fixed rules are useless, and your team is scrambling to put out fires.

This is exactly why businesses need to evolve from static rules to adaptive workflows—powered by autonomous AI agents.

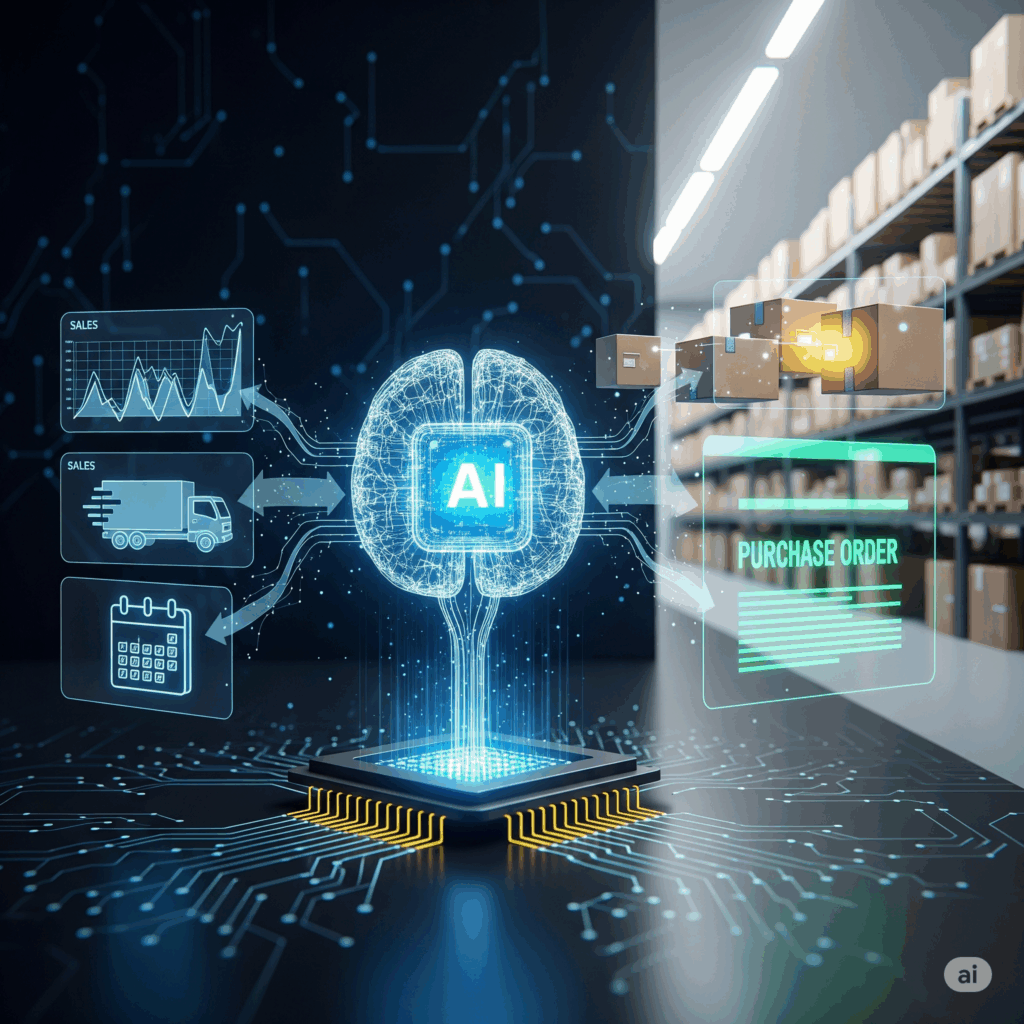

An Inside Look: How My AI Inventory Agent Works

To tackle this challenge head-on, I recently designed an AI agent that does more than just count units. It builds a living, breathing picture of the entire supply chain.

I like to think of it as having three parts: the senses, the brain, and the hands.

Step 1: The Senses (Gathering the Full Story)

First, the agent doesn’t just look at one number in a database. It constantly pulls in data from all over the business to get a 360-degree view. This includes:

- Real-time sales data from your CRM or e-commerce platform.

- Supplier updates, including current lead times and shipping statuses.

- Internal calendars for upcoming marketing promotions or seasonal sales.

- External factors like public holidays or even weather forecasts that could snarl logistics.

Step 2: The Brain (Predicting What’s Next)

This is where the real intelligence comes in. Instead of relying on a fixed reorder point, the agent uses all that data to build a dynamic forecast. It’s constantly asking questions like:

“Given the upcoming holiday promotion and the current sales velocity, what is the predicted demand for this product over the next 30 days?”

This prediction isn’t a one-time guess; it updates in real-time as new sales data or shipping information flows in.

Step 3: The Hands (Taking Smart, Autonomous Action)

Based on its predictions, the agent takes action on its own to keep everything optimized. It can:

- Generate and place optimized purchase orders with suppliers at the perfect time.

- Recommend stock transfers between different warehouses to meet shifting regional demand.

- Proactively flag an item that is at high risk of a future stockout, giving managers a heads-up long before it becomes a crisis.

The result is a workflow that isn’t just automated; it’s adaptive. It learns, anticipates, and acts to create a resilient, efficient, and intelligent supply chain.

It’s the crucial difference between a system that blindly follows instructions and one that truly thinks.

Is your supply chain still reactive, or is it becoming predictive? Share your thoughts in the comments!

#InventoryManagement #SupplyChain #AI #Automation #PredictiveAnalytics #AIAgents #DigitalTransformation #ML